Much of our success comes from the integration of our manufacturing, distribution, retail, and development operations. We distribute 75% of what we sell in our shops. Vertical integration allows us to take out the middle man and enables Stewart’s to offer products at a high quality and at a low cost for our customers. Follow along with this tour of our Manufacturing and Distribution plant located in Greenfield, NY to see how we do it all for you.

We Are Your Dairy

Stewart’s Milk is Fresh & Local! The process starts with our neighbors – local family farms that care for their animals and produce high quality milk. We visit the farms almost daily to pick up the fresh milk and bring it to our dairy in Greenfield, NY. We work with 19 local farms, when you choose Stewart’s milk and dairy you are supporting your neighbors and their families.

The Raw Milk Receiving Bay

The receiving bay is where our Stewart’s trucks unload the milk brought in from the local farms.

The check in process involves a variety of tests to ensure the milk is good quality. The first test may surprise you, using advanced tools, our noses! You can tell a lot about the batch by the smell. We then turn to technology and check for bacteria and antibiotics – neither are allowed through the door.

Silos

Once unloaded, the milk is stored in one of our two 30,000 gallon silos. We have two so one can be made squeaky clean while the other is in use.

Pasteurization

Let’s talk about pasteurization, it’s why Stewart’s Fresh & Local milk tastes better and is better for you. We pasteurize our milk but do not ultra-pasteurize it like other brands. Ultra-pasteurizing overheats the delicate milk for a longer time and gives it a cooked flavor. It also can break down many of the beneficial nutrients. We can minimally process our milk because it comes fresh from local farms and does not need to travel across the country to get to you.

The Separator and Mixing Valves

Some people prefer whole milk, others prefer 2%, 1%, or Fat Free milk. So how do we make it in just the right percentage? After the milk is cooled, we run it through the separator which separates the Fat Free milk and the cream completely. The next step is to add the right amount of cream back into the Fat Free milk to create 1%, 2%, and whole milk. So, Fat Free is already done, right? Nope. Stewart’s Fat Free milk is creamier than other brands because we add milk solids that helps the flavor and feel without adding fat and calories.

The Homogenizer

Modern technology making your life easy. No need to shake your milk anymore, it is now run through a homogenizer that used pressure to push the fat globules through tiny holes to break it up. If your milk was not homogenized, the cream would rise to the top.

The Flavor Blenders

It’s Flavor Time! To make chocolate milk we feed our cows large quantities of the finest cocoa. Wait, what? No, that’s not true we just wanted to see if you were paying attention. A giant blender is used to mix in the flavors like chocolate, strawberry and cappuccino.

These blenders are also used to make Stewart’s Refreshers in milks, teas, juice, coffees, energy drinks and lemonade. Why pay 50% more for brands that can sit on the shelves for months? Stewart’s Refreshers are made cold and kept cold for fresh flavor.

The Blow Mold Room

Let us make your life easy with the perfect sized package. From paper cartons in half gallon, quart, pint, and half pint to plastic gallon, half gallon, 20 oz, and 16 oz sizes. We make these plastic bottles here at the plant. The excess plastic is cut off and reused to reduce the amount of waste.

The Filling Room

Bottles are filled with milk or refreshers in the dairy filling room. They are each placed on a pedestal and when they rise, it opens a valve to dispense the product. What’s your flavor?

Cooler

Cases of product are stacked and pushed out to an in-floor conveyer which takes them to a cooler.

The Plating Room

The plating room is in our lab. This is where milk is opened and tested for bacteria counts. Milk is tested 7 days after it is packaged, and again at 14 days to make sure it makes it through the end of the code date.

We Are Your Ice Cream Shop

Some of the lucky cream gets transported via piping to the ice cream factory down the hall. Ice cream mix (a combination of cream and milk) is pumped in from the dairy. It is pasteurized, homogenized, cooled back down and placed in a storage tank.

Peanut Butter Pandemonium, Crumbs Along the Mohawk, Brownie Cookie Sundae – Stewart’s Shops has a lot of choices when it comes to ice cream, sherbet, and frozen yogurt. How do we make all these delicious options? Ice cream is delicate, and we treat it with care from start to finish.

Experimenting and taste testing

Creating the flavors is half of the fun! We try out all sorts of creative combinations until we find just the right balance of flavors for you.

It’s Flavor Time!

Every flavor starts with either a white base or a chocolate base and just the right amount of air. It’s like Goldie Locks, too much air and the ice cream is light, too little air and the texture is like a fudgsicle. Stewart’s ice cream has less air than many of the supermarket brands that are trying to cut corners to lower the price. Stewart’s pre-packaged pint ice cream has even less air than the cone counter or half gallon packages. This is super-rich ice cream that is denser and made with more cream and goodies.

Ingredient Feeder

Candy pieces and nuts are blended into the ice cream by using an ingredient feeder, while chocolate, peanut butter, and other sauces are swirled in separately.

Our ice cream comes out similar in texture to soft serve. After packaging, it is placed in a hardening room that is 30 degrees below zero. The faster the freeze, the better the quality of the ice cream.

Freezer

Our recently expanded 15,000 square foot freezer stores enough product to fill 110 tractor trailers. That’s nearly 3 (very cold) basketball courts!

Stewart’s Kitchen – We MOO for You!

Many of you know about our fresh milk that we get from local farms and our delicious ice cream, but you may be surprised at just how many other things we make ourselves in the Stewart’s kitchen. Our chefs are busy making your favorites like, macaroni and cheese, chili, chicken alfredo, penne marinara, meatballs, soups, egg/tuna/chicken salads and more. It’s all made by friendly Partners who care as owners of the business.

Food Lab

In the food lab we continually test incoming products for consistency in flavor, texture and size. Just a few of the products we test include chicken tenders, hot dogs, coffee, chips, and bread. We are especially detail oriented due to our dairy background. Dairy is a very regulated industry and we carry those best practices to other areas of our food service. Many times we tell a supplier they have a problem before they even realize it.

The Warehouse

Here at the Stewart’s Distribution and Manufacturing plant, we do everything we can to support our shops. This gives our partners more time to help you get in and out of our shops quickly. We also provide this support so the products you expect to find at your shop are as fresh as can be and always in stock. We fill shop orders with over 99% precision through a process called single picking. This means shops can opt to have as little as just one of a particular product sent at a time, instead of an entire case. Keeping inventory down keeps our prices down. Single picking also leads to fresher products and better product selection in our shops. How does it work? Our “pickers” are relayed shop orders through a voice automated system. It relays the aisle number and the amount needed of each product.

Order Fulfillment

From hot coffee to ice cream, enjoying Stewart’s products requires a cup, dish, or cone. We keep our shops stocked for you by filling orders in our warehouse.

Green Initiatives

Here you see two ways Stewart’s Shops recycles. First, our plastic milk and Refresher bottles come back to the plant to be recycled. We recycle 200,000 lbs of plastic every year. The green plastic totes are reused to ship products to our shops.

Here is another surprising number. We recycle nearly 4 million pounds of cardboard each year!

Bread Department

Bread, donut, and snack area – your bread is protected with reusable plastic crates. Our warehouse receives one to two truckloads of bread each night. There are 12,000 loaves on each truckload. We ship 2 million loaves of bread each year.

We ship 750,000 boxes of donuts each year.

Pricing

For many of our products, we put price stickers on before shipping. This helps our shop partners be more efficient when restocking store shelves.

The Candy Room

We are your candy shop with gums, mints, fruity candies, and chocolate. The candy room is kept at a chilly 68 degrees to keep all that chocolate from melting. Any hotter and we’d have a sticky situation!

Loading and Receiving Dock

At the loading and receiving dock, we start receiving products at 6 am. Around noon, this area turns into a loading dock of items to be sent out to our shops. The contents of the truck are organized in the order of each stop, with the last delivery first. Then, the trucks are loaded, and deliveries are smooth and accurate at each of our shops.

The Beverage Center

At Stewart’s Shops there are more than 100 ways to get UnThirsty! Our warehouse houses about 150 different beverages, including soda, beer, and water. We have our own beer warehouse permit, cutting out the middleman and saving you money.

Grocery and More

Let us make your life easier. The grocery area of our warehouse contains more than 550 different items. This department ships the most totes – about 1,500 to 2,500 a day.

There are more than 40 varieties of potato chips and over 15 varieties of coffee in our warehouse. In all, we ship 650 cases of chips and coffee per day to our shops.

Stewart’s sends about 40,000 cartons of cigarettes to our shops each week. We place a New York State or Vermont tax stamp on each pack before it is sent out. Marlboro is the most popular brand.

The Hauling Department

The Stewart’s hauling operation is responsible for product and gasoline delivery to shops as well as raw milk pickups from our producers. We can do this safely and efficiently with the use of over 55 vehicles and over 100 drivers, 364 days a year (every day except Christmas Day).

The Truck Wash

The truck washing bay keeps our trucks looking good and the truck repair facility keeps our fleet operating safely.

Shop Services

Shop maintenance and dry good needs are taking care of from the shop services department located in, what we call, building 2. This warehouse fills orders for electrical parts, display parts, and even paper towel dispensers. This is also where all our cups, napkins, plates and uniforms are stored. We even build the cabinets for the shops here.

The Appliance Repair Center

We repair as many as 8,000 pieces of equipment a year, including coffee warmers, hot dog roller grills, and rotisseries. The items are stripped down and reassembled, then sent back to the shop as close to ‘brand new’ as possible. This is so everything we use to make that delicious food and coffee produces a consistent product.

The Appliance Washroom

The washroom is where our shop appliances are cleaned and sanitized. All appliances are on a schedule to be swapped out for cleaning, keeping them shiny and clean for you; from your coffee to your hot dog, great taste is guaranteed.

The Tech Center

Stewart’s Shops has its own tech center. Our tech center provides service for shop equipment including ATMs, cash registers, and printers. Techs will be sent out to do repairs right at the shop as needed. We do this to ensure when you go to a Stewart’s shop your transactions run smoothly.

The Print Shop

Stewart’s also has a print shop, where 90 percent of the signs you see in our shop, are printed. Doing the printing in-house saves money, so the marketing costs are not passed along to you. The print shop also helps print and distribute gift certificates, forms and envelopes used in daily operations, and even engrave our Partners’ name tags.

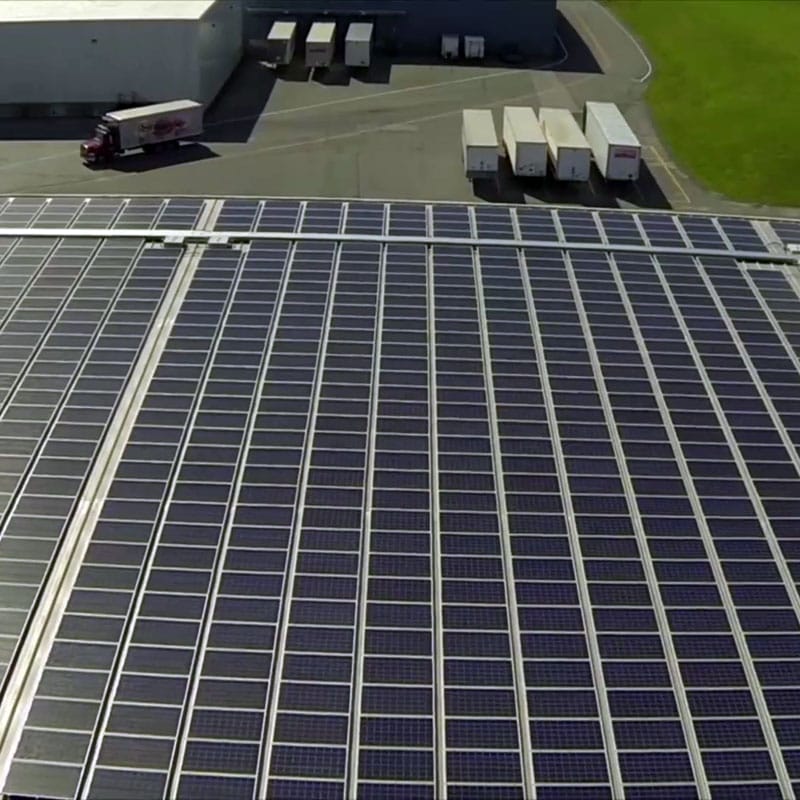

Solar Panels

On top of it all, about 2,400 solar panels have been installed on our rooftop. These panels are expected to save the company about $40,000 per year. Check out the progress